Yet another long awaited update…

So…Obviously the thought that I may be a little more frequent in my blog updates was completely and totally ignored. It’s been many many moons since the last update, and of course, I’m still working on the layout. Here’s a rough idea of what’s been going on:

- All the locos in the fleet are now equipped with keepalives. More specifically, they’re ESU PowerPack Minis, and the locos are all Loksound too. I do agree they’re pricey, but they are the smallest, easiest to find space for, and with not needing to be disconnected or switched off during programming, it’s well worth the many extra dollars. Athearn’s released their GP38-2’s and I did acquire one for the fleet and the install of a Loksound Select Direct and Powerpack Mini went quite well. I haven’t had a chance to actually run it in service though because:

- COVID-19 struck about a year ago, and while I was working for most of the time, there was about a month and a half where I was working 4 days a week instead of five. With that extra day off each week, I figured I’d bite the bullet and actually redo the entire staging yard to support Marine Interchange. More on that specific bit shortly, but with the scalehouse coming to the layout, and a bunch of extra time, I figured it would be well worthwhile to add some more operations to the layout and am adding a ferry slip. To do that necessitated a full on lifting of the majority of the trackage in the yard and laying it again in a different configuration. I’m also making the yard slightly more reminiscent of the prototype, though only in that the caboose track is going to be adjacent to the scalehouse, the engine service and RIP tracks are going to be present, and I’ve got a pair of team tracks to service. I also sold off four 40/30″ radius curved turnouts as they wouldn’t fit along with a funky crossover. The remaining turnouts were repurposed elsewhere in the yard and more than a few new turnouts were made, including the acquisition of yet another turnout assembly fixture from Fast Tracks capable of building curved #8 25/32″ radius turnouts. I built a few of them, including one during a Facebook Live event. At some point when the layout is clean, I’ll possibly take some pictures and post an updated track plan.

- As indicated above, I decided that I really, REALLY, wanted marine interchange. This goes back to the early track plans where I had planned on having a boat to switch, but had to give up after discovering a few gotchas during the building of the layout space. After doing more than a few switchings of the Doris Yorke and the Trailer Princess at David Bedard’s place back when he had the E&N, I wanted it still for myself. On the prototype back in the day, the Seaspan Doris and the Carrier Princess were the primary boats doing the work of transporting railcars between Vancouver and Nanaimo. I do admit, I was tempted to get the Doris Yorke from David when he was selling it, but decided that I really wanted the Carrier Princess instead. So I’m going to be building a scale model of the boat and putting it on wheels so I can actually “sail” it into and out of a ferry slip that is going to be roughly underneath where the middle deck Victoria Sub goes into the helix. This will allow me to give more work to the Nanaimo switch job – they’ll be responsible for unloading and loading the boat, classifying the cars going to the Port Freight, the Courtenay Turn and the Nanaimo switch job. I have my doubts that I’ll be pulling and spotting traffic that headed to Duncan and Victora though. The yard isn’t big enough for all of it.

This is going to require my spray booth to find another home – quite possibly out in the garage or perhaps even in my office upstairs. - In the rebuild of the yard, I decided early on that I wanted the ability to control the turnouts from touch panels. This eliminates the need for operators to know the switch numbers and for me to build physical panels. With all the turnouts being controlled by servos driven by Quad-LN’s from Tam Valley Depot, it should have been an easy thing to do up. Except…Well, let’s put it this way. I should’ve been able to have this entire yard done and controlled months ago if it weren’t for a number of things being problematic, like my Locobuffer-USB missing commands, the Zephyr command station not putting enough voltage into RailSync, the old iPad I acquired for the purpose not being new enough to handle the panels JMRI was handing out, and changing out the layout computer to one that is a little faster and equipped with more memory. It’s been very frustrating at times, but thankfully, everything is now properly working. I’m still working on the panels, but that should be completed reasonably soon.

- I’ve found a number of the servos in Port Alberni to be hanging from the layout every now and then, because the double sided tape I was using to hold them to the layout was losing it’s bond under the heat from the servo. Cam has been on my case for a while about getting a mount made for them so I can screw them to the layout. With the help of Chris Caswell in Nanaimo and his laser cutter (he runs BC Robotics), I’ve managed to design, prototype and make a bunch of three piece wooden mounts that are absolutely brilliant at having a servo do the work it needs without requiring a huge amount of space to do so, but yet providing a neat ability to adjust the position of the servo if needed after screwing it into the benchwork. My friend Andrew Underwood has these installed on his small switching layout and really likes them. I like them too…so much so that:

- I’m going to pull all the bullfrogs from the layout. I’ve already replaced the lower deck of the layout with Tortoises controlled by the Signalogic Systems Tortoise Controllers and Switch Control Panels, and will be replacing the remaining bullfrogs with servos due to the deck height limitations. This way, I can have all the turnouts (save for the ones in the Wellcox yard) controlled by a common interface that provides for route indication from the fascia.

- I finished up the process of acquiring, stripping, painting and decalling of a bunch of 50′ Proto2000 Flatcars into CP Rail Action Red. I now have proper spacer cars for the loads of poles coming out of the Courtenay Area. Also acquired a lot of Action Green boxcars for paper service. I still have two cars that I bought undecorated to suitably modify, paint and decal. Just need some pulling eyes to complete the modifications…Which leads me to my next point:

- I’m getting a 3D printer. David pointed out the fact the Elegoo Mars printers (he has a pair of them) were available on sale at Amazon for just $220, delivered, and I couldn’t really pass it up. Add a bottle of resin, a UV Curing lamp, cabinet for said lamp, and you’re virtually all set for less than $300. Plenty of detail parts will be coming from that over the next while, and perhaps even a caboose? It’ll be a rabbit hole to be absolutely certain!

Maybe, just maybe I’ll find more time to do updates to the blog, but this will do for the time being. See you in a couple years!

Lots of time, some progress

Yup. Still neglecting the blog.

But not really neglecting the layout.

It’s been over two years since the last blog post and I’ve managed to accomplish a few things:

1. Lighting. While the room lighting hasn’t changed (it’s still quite bright fluorescent at 6500K temperature), I have installed all the lighting for the lower decks. It’s all LED strip lights, stuck to narrow strips of white coroplast, and dependent on how deep the deck is determined whether I lit with one strip or two.

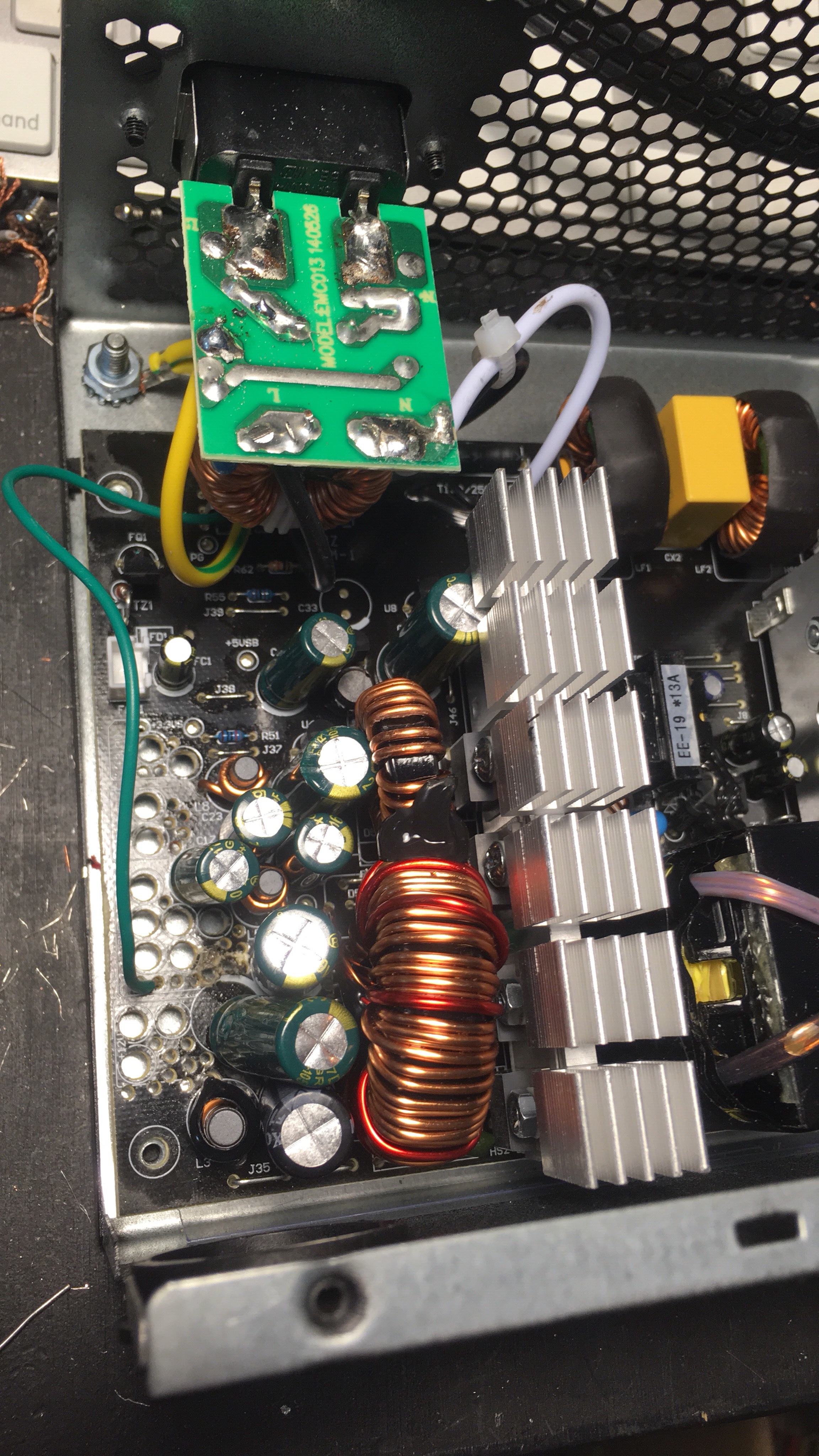

I also needed to power the many many meters of LED’s, and wasn’t terribly interested in using cheaper power supplies from China due to the noisy fans. I also happened to have a spare 625W ATX computer power supply kicking around not doing much so I decided to pop the cover, unsolder the loom of wire off the main board and then hook up some beefy wire to a terminal strip on the outside, where I connected the bus wire coming from the LED’s. Not coincidentally, the power supplies are located near the rest of the electronics, primarily because that’s a central point for everything. I did realize rather quickly however that the one power supply was not going to be enough. Another supply, this time 700W was purchased and similarly modified. At this point, Cam and I wondered it if wouldn’t be a bad idea to actually put these two power supplies on their own dedicated circuit in the breaker panel since they were going to be drawing so many amps….I figured it would be a good idea and had a spare breaker but no desire to bust open drywall to install the wire for it. I made some inquiries and found armored cable could be mounted on the surface and legally used, so we acquired more than a few meters of 14/2 BX, a surface mount box and a couple of switched receptacles, and had the entire shebang installed in an afternoon. Further work and testing proved all was good.

2. The ballast spur near Mud Bay siding has been removed. We’re now moving towards scenery and it was getting kinda awkward with how it was going to be done that far back, what with the half-loops of track behind there.

Besides, the ballast for the island was typically loaded out at Fiddick’s pit, south of Nanaimo. So, Cam and I removed the entire shebang.

3. I’ve had a few ops sessions, and for the most part, they’ve gone really well. One of them was for the guys from Rapido Trains, which included Jason, Dan and other Dan. Oh yeah, and Dan Hamilton was in on it too.

I do realize that despite my best efforts with track cleaning and wheel cleaning that I do need to install keep alive’s into the fleet as sound cutting in and out is REALLY annoying. It’ll be fun I’m sure…

4. I built Parksville Station. Many and huge thanks to David Bedard for providing the tips, assistance, and overall inspiration to build it!

I still need to build a foundation to sit it on, plus a walkway and platform at some point…(plus everything else there!) I’m really happy with this one.

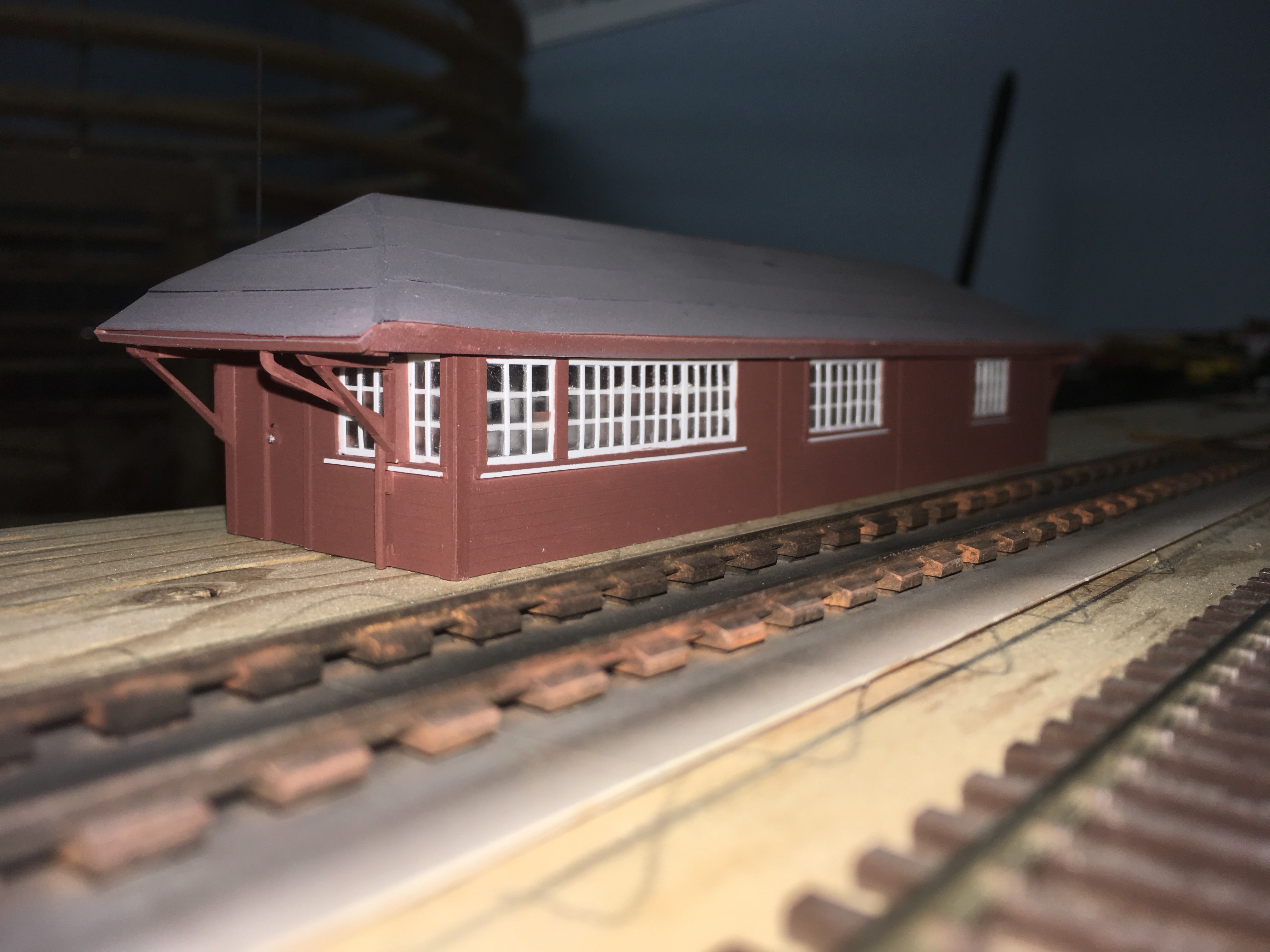

5. Speaking of David…he’s decided to change locations for his layout and as a result, all the structures plus the magnificent boats he scratchbuilt are going away. I bought the Wellcox Scale House (complete with scale track) plus a couple of the shelters which I’ll put to use on the layout and spent a bit of time quite recently installing. The crossover beside the scale track is also brand new to Wellcox and was just finished this afternoon.

So lots more work to do…

But now that I’m retired from the SUPERTRAIN Committee, I’m looking forward to putting more time into the layout. And maybe…just maybe I’ll also update the blog a little more frequently too.

Have I neglected my blog or what?

I’ve got a fair bit of time now to bring you guys and girls up to speed if you haven’t been able to see the layout in person, though I don’t know how many photos I have on my phone to share. Anyhow, here’s the story.

I could have had track completely finished a long time ago. But I decided that I wanted the trestle at Vancouver Island Gas in a more complete state. Unfortunately it was not to be. Cam wanted to figure out the best way to anchor the trestle to the benchwork but still have a good base for the scenery. The scenery would also dictate the angle bracing on the bents. So to have the bents actually in and on top of the plywood, and have scenery that drops from track level to much below track level would require some creative fiddling with the blue styrofoam that would support the shell. Here’s Cam checking to see if the work actually gives some level track:

Meanwhile I had also been working on the track into the former engine house at Port Alberni. Using two or three different thicknesses of styrene sheet, and a large amount of styrene cement (I was pouring it out of the bottle to get it to laminate the sheets together…) I was able to get the foundation started. I’ll need to build more up to match the rail height, but for now I just needed to get the only the rail level to what was coming in from outside. Unfortunate that I didn’t take more progress pictures of that specific detail. Following that, I wired up the remainder of the yard trackage and the plywood division to the track bus, so the full yard was powered. But over the week between Christmas and New Years, both Cam and I were off work and we got those two bits of track installed, clean things up and finalize the trackage between the Plywood Division and the Port Alberni yard. I of course would leave a few spikes out.The first day of 2016 would be the final spike ceremony. Invitations were sent out a couple weeks prior to have a few friends and supporters over to see the final spike being driven into the track. Kevin Pyle brought a spike maul, used for driving spikes on the prototype, and I figured “why not?” Using the spike maul and a nail set was a little awkward, but it didn’t take more than three taps with that huge hammer to set the spike in place.

Cam received the honour of driving the final spike. He initially declined to use the spike maul but decided to use it for the “shiggles” factor.

Here is where I would insert a link to the video that was shot, but stupid me shot Cam’s video upside down and thankfully software exists to rotate the video to be right side up, but I just don’t have time at this time of year to edit it and make a better product so you’ll have to visit this page later to see the video.

After the spikes were set in place, trains were fired up and run over most of the layout. I say most because quite a few servos were not yet installed into Port Alberni yard so switching there wasn’t done much.

Since that date, more work was done in getting the servos installed and hooked up to the Tam Valley Depot Octopus III controllers. After some discussion with Kevin Rudko of Signalogic Systems, it was discovered that his switch control panels intended for use with his switch controllers would actually work with the Octopus controllers, with only some slight wiring tweaks. The only real hitch is that using momentary switch inputs could lead to some undesired action on the servos, but time will tell whether this was going to be a huge concern or not.

The next major event would be the Calgary Model Railway Society’s Layout Tours, happening at the end of February. Much cleaning was done, trains staged and switch lists generated, and my huge thanks to Dave Chomyn for coming over to run those trains during the six hours that the tour was running. We had 44 people over to see the layout that Sunday, which for me, was a huge success. Lots of people left favourable comments in the guest book, one guy who came over with a hatred for multi-deck layouts left quite impressed and now considering the idea has merit, and even a few women were impressed. Virtually all of them will be back for future tours to see how the scenery is progressing, and see how many of the “thousands upon thousands of trees” I’ve planted!

Of course, I’m also heavily involved in the organizing of SUPERTRAIN, Canada’s Largest Model Train Show. This year, I’m working on the Registrar duties (thanks to Jim Ironside for being my co-registrar), graphics design and printing, and new this year, organizing the Shuttle Bus operation between a large Transit park and ride lot and the show venue. Being able to combine my transit-geek and friendships with a bunch of bus drivers to help the show has been quite rewarding. This show takes up a lot of my time in the few months leading up to the show and I’m thankful for the opportunity to even get downstairs every now and then.

At some point I’ll be able to get back to the GP9’s that are needing to be completed, get some more scenery work done and who knows what else… Until then, keep your stick on the ice.

Another omnibus update

So it’s again been a while since I’ve posted an update. Seems to be a common theme around here… And admittedly, I’m going from memory here so please excuse me if I forget anything. (Cam, this is your opportunity to comment on anything I’ve forgotten!)

I was quite busy in the lead-up to SUPERTRAIN, ensuring things with the show were taken care of, but also with the layout at home since I knew a few people coming to town for the show would also appreciate an ops session. (Yet another common theme here…) so track cleaning, ensuring the Port Alberni staging yard is operational, motive power is good and that I’ve got rolling stock ready. Also worked on getting the dispatcher’s office somewhat cleaned up so I could use it. The chair was rather dusty!

The ops session went reasonably well, but with some operators being unfamiliar with the layout and the work extra running dead on hours left a few things to be desired. Namely, need to get a car control system in place and while I was thinking of a computerized switch list generator, I’m thinking of going to car cards after discussing things with Grant Eastmam and Cam following the session. Still doesn’t negate the fact I need to renumber a LOT of rolling stock.

Here’s a hint to the manufacturers: more road numbers! Or even better, include a small decal sheet with numbers we can use to renumber the cars with!

Also, need to have operators more familiar with where everything is, and the dispatcher needs to write up clearances before everyone shows up. More preparation in advance of the people showing up is usually a very good thing. And of course, I wish I had a couple more passing sidings, which don’t exist on the prototype because the trains were spaced out a lot more than what they are in an ops session…

Since the ops session, I’ve been working on rolling stock and motive power, including getting a whole ton of GP9’s ready for CP paint. But that will have to wait for another post…my train ride is almost done. See ya!

March 23, 2014

A brief update this time around.

Cam was over yesterday with a mutual friend from the Free-mo group named Carl. The primary reason was to show Carl the layout and the progress since he last saw it several years ago.

After Carl left, I figured we could get “something” done on the layout.

We decided on benchwork… And then proceeded to get the trackboard completed down the hill into Port Alberni, which we successfully completed along with a section of the plywood representing the paper plant and the first part of the yard. We’ll hopefully tackle cork and at least some trackage before SUPERTRAIN, as I’m wanting another ops session with some friends visiting from Toronto just after the show. I’d like to be able to run the Port Freight all the way into Port Alberni instead of just to Arrowsmith…

Cheers!

January 11, 2014

Yes, it’s been a little while, again.

Still busy with SUPERTRAIN stuff, but I have been trying to keep progress going forward in the basement. Maybe not really in the trackwork/benchwork realm but in the rolling stock. I now have three skeleton log flats which are nearly ready for decals and a couple 50′ long flat cars suitable for idler flats. More on the five pack later.

Cam has also been really busy over the week getting all the last details added and painted on 3000 and 3004, in preparation for the ‘Homecoming’. Friday night he escaped from work a little early and came with me to Dave’s place to get some last minute touch-ups and details done. All tested and these things are awesome.

The next day (ie: Saturday/today according to my dating scheme here), I was busy doing a ton of cleaning in preparation for the party. Cam arrived around 1pm and we got to work on niggling issues with the layout…specifically the problem turnouts, at Parksville and ICG Nanaimo. The former was needing rails spiked to the ties and some minor adjustments, the latter needed to be shifted and spiked. Will still need some work, so some flags (aka yellow and green pushpins) were setup and and a Daily Bulletin was issued to advise of the slow order through the turnout.

I also did a thorough vacuuming of the track and thought that would be all. Not quite as it turned out.

Guys started showing up just prior to the appointed time and the layout was deemed okay to turn on (oh yeah, forgot to mention… A fair number of frogs in the staging yard needed gapping) and the locos were fired up, assigned and coupled up to the Courtenay turn and Cam had the Honours to be the engineer to run the train containing a lot of his work (3000 and 3004, as well as the skeleton log flats) out to the end of the line and back.

That’s Jeff Simpson in the foreground admiring the train with Cam running in the background.

Jeff was accompanied by Josh Soles and Matt Cummins who gladly accepted a throttle and 6101 to run VIA 198 and 199 out to Courtenay and back. A little quickly mind, but at least most of the crews running freights gave the passenger service minimal delays. Chuck Johnstone, Tyler Federoshyn, Dan Hamilton and Kevin Pyle also made appearances and some of them had opportunities to run trains as well. Kevin has built a few of the Kaslo skeleton log flats and agreed that they’re too light to run empty, but he’s got a good means to produce the poles… I’ll be leaning on him for a drill press and his expertise to make the poles I need for the two industries loading them…

All in all, a good day, summed up in this picture of Josh admiring the two GP38AC’s:

It will be fixed

In some respects, building something gives you knowledge of how something goes together.

It also (hopefully) gives you knowledge of how to repair it.

Due to the cold outside, the non-functioning humidifier on the furnace and the fact the basement is warmer now than in the summer led to another rather nasty kink in a really unfortunate spot: Parksville Junction.

This shot, taken from above, illustrates what happens when things aren’t allowed to breathe.

The last time this happened, at the ballast spur turnout on the lower deck, I cut the rails and they managed to straighten themselves out.

Sadly, this didn’t happen here. After cutting some gaps, the rails did not return to where they should. As a result, some selective repair will now have to take place.

Here’s the progress on the demolition:

Wish me luck!

Modelling…

So the past few weeks have been primarily occupied with getting web pages done up for SUPERTRAIN – not so much for the public, but for the people who will bring their displays and wares to the show.

But that’s not to say I haven’t been doing nothing for the layout. Thanks to Dave Bedard for inviting Cam and I down to his place over a few evenings over the past few occasional weekends to do some modelling. He’s worked on some of his locomotives, a couple of mine (those GP38AC’s you saw in Jason Shron’s pictures? Now painted and decoderized, just getting the final details added like handrails, grab irons, lift rings, etc. I’ll fill you in on those, with pictures, once they’re complete.

Actually, that was more Dave and Cam’s work. I’ve been working on a rather unique car that was rather essential for the layout:

The CP skeleton log flats.

These cars are really spindly things, purpose built for carrying logs and poles. I’ll be loading them with the latter, and there in lies the challenge for modelling such a car: there’s nowhere to put weight when the car runs empty. Kaslo made a resin model but resin isn’t a heavy material, and there’s just a tiny cavity in the centre sill to put weight. To operate my layout, properly, I need to be able to deliver empty cars to the two industries in Courtenay, and the resin cars are simply not able to be made heavy enough to operate properly. Solutions were investigated, including photo-etch brass (filled with liquid gravity), shapeways metal, and borrowing the centre sill from an Atlas Trainman bulkhead flat car.

Until Cam found, quite by accident on Walthers, a kit of the very car I need, made entirely from solid cast pewter (aka, metal), from Custom Finishing. In stock for around $27, an order for four cars was quickly placed and picked up when they arrived at Hobbytech.

The kits were produced back in the late 90’s and thankfully didn’t sell out (either that or the molds still function) so I could get them some 15 years later.

They are as old school as you can imagine. Though the direction sheet indicates these are an easy build, nothing could be farther from the truth. The amount of filing and fiddling with these kits is the most I have ever seen…I would charitably say that between Cam and I, we’ve filed about a half-ounce of pewter from the parts that make up a single car.

But the results I think will be more than worth the effort. Especially when I think of how much time I would’ve spent trying to learn and design the car from photos and crude folio drawings, without any assurance of the resulting parts coming out to my satisfaction.

You tell me: doesn’t this partially finished car look pretty good?

The car is sitting on ExactRail 70 ton trucks (complete with semi-scale 33″ wheels) with Kadee 78 couplers. The kit needs a thorough washing, shimming the two centre bunks and gluing to the sill, but otherwise ready for paint and decals. Two other cars are in process, coming close to the same state, and the fourth hasn’t come out of the bag yet. I’m likely going to leave it like that to get a rough idea what the starting and finishing weights are.

I suppose the caboose deserves mention too. It’s an older Athearn end-cupola steel caboose, factory dipp…err, painted in CP script for international service. That scheme is way old for my layout, so out came the windows, off came the roof walk and cupola. After a good long soak in 99% iso, plus plenty of scrubbing, the car is as you see it now. Cam also plugged the old roof walk holes, and it’ll be seeing a few coats of True Line Trains Action Yellow and decalled for CP Rail. So after that is finished and I have another one arriving from Florida via eBay, I’ll have, I think, enough cabeese to operate the layout. But all of them will be stand-ins.

And that is a bit of a shame. The cupola is wrong, the roof is supposed to be a peaked raised panel roof instead of a curved roof, and the windows are not right. Yes, they’re steel, have the cupola at the end and painted in the right colours. And for now, that will do. There just isn’t a kit (yet) available for the proper caboose, and I’m not going to scratchbuild five of them either. I did have an opportunity to get a proper brass caboose, painted in the right paint scheme, for $300-ish but the wife vetoed that purchase. And in some respect, I’m glad she did. Because what the island had was a consistent fleet of cabeese, and having one correct and several stand-ins would’ve made the correct one stick out like a sore thumb. So until I’m able to do a wholesale replacement, the stand-ins will have to do.

Sorry for the novel on such a tiny aspect of the building, but it’s something to read…

Cheers!

Best photo yet!

I think this photo warrants it’s own post. Cam (left) and I standing beside a few trains (Arrowsmith on top, Parksville – complete with in-progress units 3000 and 3004, and Mud Bay below) and looking quite thrilled at the progress made on the layout.

Photo undeniably by Jason Shron, stolen without permission from Rapido Train’s blog.

July 31, 2012

Spent the evening tonight doing a lot of cleaning up in the basement. Things were getting out of hand, messes were everywhere and for some reason, that one sweepstick (30″ radius) was still missing.

So, I used some of those shelf brackets, put them up fairly high up on the standards and put the 2″ strips of wood up there, additional standards yet to be installed and some of the additional strips of wood. The larger pieces all got consolidated as well out of the way and the floor thoroughly swept.

One could say I made a clean sweep, as I did locate the sweepstick on the floor.

Oh yeah, the other major change was the moving of the chop saw. For quite some time, it resided up against the wall that was soon to have benchwork installed on it. It’s now in front of Bryn, with a sheet of plastic stretched across the three decks behind the chop saw to protect it from flying debris and a whole ton of sawdust.

All this done to facilitate more work this upcoming long weekend!

Cheers!

Completely unrelated to the model railway

I suppose this is worthy enough of a post, even though the only times I’ve been down to the basement over the past while were to access the contents of the fridge and freezer at the base of the stairs…

The Southern Railway of Vancouver Island and it’s owner, the Island Corridor Foundation, have managed to convince the Federal and Provincial governments to buck up the 15 million to do enough rehabilitation to the railway’s Victoria Sub to reinstate the Dayliner service. Initially, it’ll run from Nanaimo to Vic West – owing to the removal of the Blue Bridge into Victoria, the railway won’t serve Victoria proper again – but in time, I’m hoping the line all the way to Courtenay will see passenger service again.

It would be a very unsafe bet to make that I don’t travel out to Vancouver Island to ride the train when it comes back into service!

I’m exceedingly happy about this news!

March 25, 2012

I’m sure you’ve visited the blog at least once or twice in the past month wondering whether I’m still alive.

Yes, I am. Apologies but as of late, haven’t really had much time. Been busy with getting things ready to go for SUPERTRAIN (I do the design work for all the printed materials, so it’s been a fair bit of work) and just haven’t had any ability/inclination to head downstairs.

Once the show wraps up, will likely head back down to get some more done.

Jon

Smartphone Friendly!

I host my own WordPress site. Until today, that meant a lot of people who view my site on a smartphone or an iPad got to view the regular desktop version of the website. Given the links and intended large size of the screen, this made for a poor user experience. (Those who host their blogs on WordPress.com didn’t have this to worry about…)

But starting today, those who access my site from a small device like an iPhone or an Android device can now see the content in a format much more suited to their screen, and is much better on bandwidth consumed in accessing the site, so your data plan won’t get smacked just from viewing the blog. Note that you will still have access to all the content, just in a different format.

If you have any feedback on this, either leave a comment on this post or send me an email.

Cheers!

I host a prolific manufacturer

Amazing what happens when things fall into place…

A few days ago I contacted Jason Shron of Rapido Trains to advise I had taken a couple days off work to help him out with his “Canadian on tour” while he was here in Calgary. He readily agreed to this and we met up a short distance from my work on Tuesday evening. Things got really interesting from there… To the point that he didn’t want to stay at the hotel he booked for himself and ended up accepting my offer of my guest room when all the other hotel rooms in Calgary were taken up. The full details are available first here:

And here:

You can see a couple pictures of me and the layout on Wednesday morning. While Jason’s writing makes it look like it’s all my work, nothing could be further from the truth… This layout is just as much Cam’s as it is mine… It just happens to be in my basement and built with my funds.

Thanks for coming out Jason, and you can come back anytime for a visit. Just make sure you bring warmer clothes. 🙂

And for the rest of you… Do order a Canadian set or two. He alludes to manufacturing an RDC model but it won’t happen unless sales of the Canadian are really, really good…

Cheers!

Work still progressing

So with Taxes (ugh), house cleaning and the various bits of other things that take up my time, I’m remiss with getting updates done. Oh yeah, and also a few other things like working on Murray’s home layout.

So far, we have completed four turns on the main helix, the majority of the benchwork for the peninsula is in place (Trackboards still need to be cut and secured though) and the amount of track laid has tripled from March. Of course, that’s easy to do when the helix chews up a lot of track going around and around and around… And unfortunately, Cam and I discovered my work with the 26″ radius 60° arc design was a little flawed. When the start of the helix construction came around, we discovered the shape didn’t match the 120° arcs and the ready-rod wouldn’t work due to lack of support on many of the inside holes. So they got pitched and we’ll need a few more 120° 26″ radius arcs cut. But we’ll likely have enough to connect Parksville with the lower deck, and at some point soon, we’ll be able to run trains from the middle deck to the lower deck. Not going very far mind you, but it’s still progress.

I’ve also started building the Code 70 turnouts for the visible portions of the layout. They’ll be needed in a hurry for the Parksville area.

And with that, I think I’m going to build a few more…

Updates still coming

I’m finding time I wanted to put updates into WordPress hasn’t quite materialized as I had hoped.

I’m still wanting to post details as to what happened in the three weekends early in March as there was certainly progress on the layout, but I just want to get this live.

Cheers!

Recent Comments