So…Obviously the thought that I may be a little more frequent in my blog updates was completely and totally ignored. It’s been many many moons since the last update, and of course, I’m still working on the layout. Here’s a rough idea of what’s been going on:

- All the locos in the fleet are now equipped with keepalives. More specifically, they’re ESU PowerPack Minis, and the locos are all Loksound too. I do agree they’re pricey, but they are the smallest, easiest to find space for, and with not needing to be disconnected or switched off during programming, it’s well worth the many extra dollars. Athearn’s released their GP38-2’s and I did acquire one for the fleet and the install of a Loksound Select Direct and Powerpack Mini went quite well. I haven’t had a chance to actually run it in service though because:

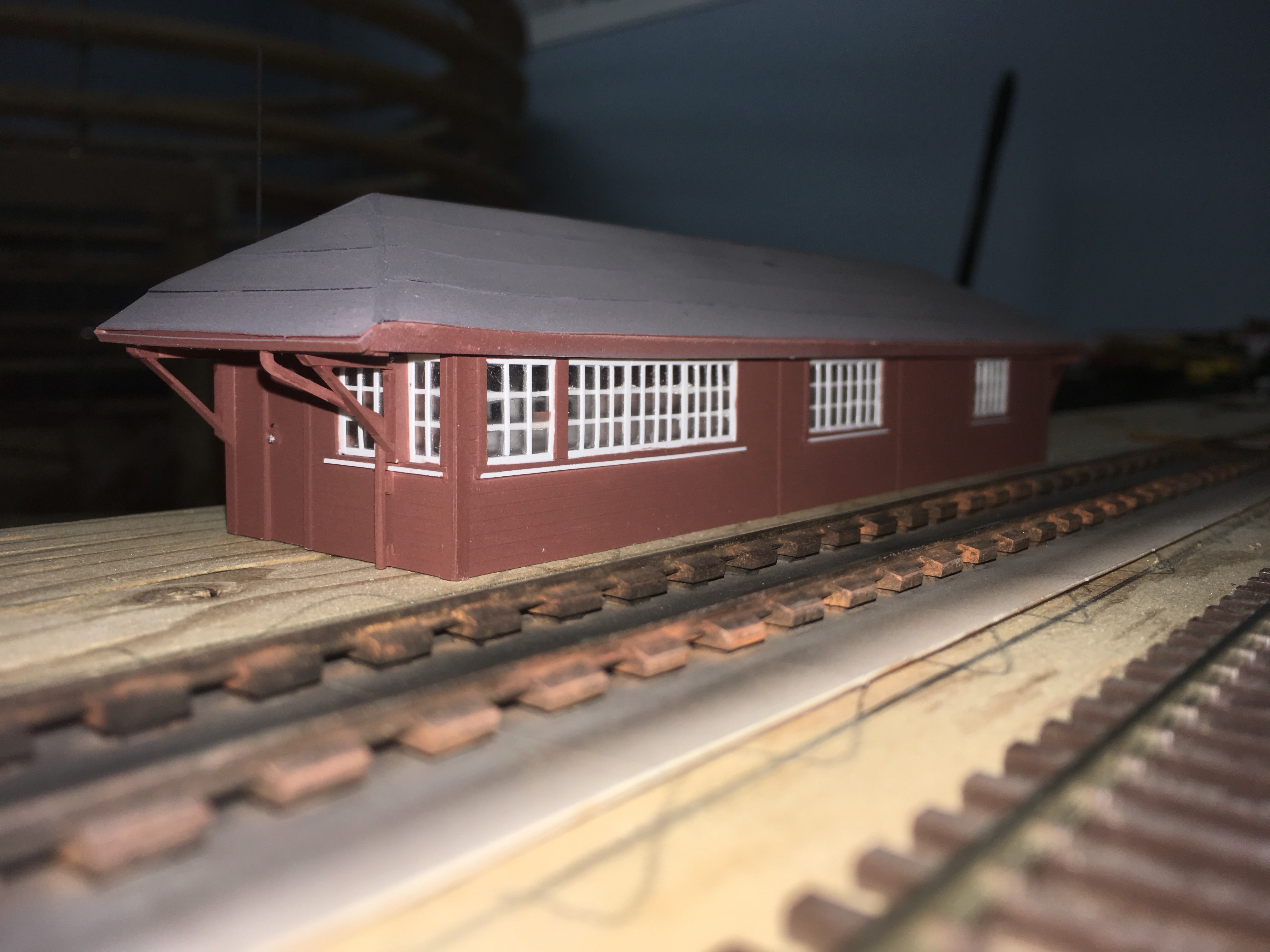

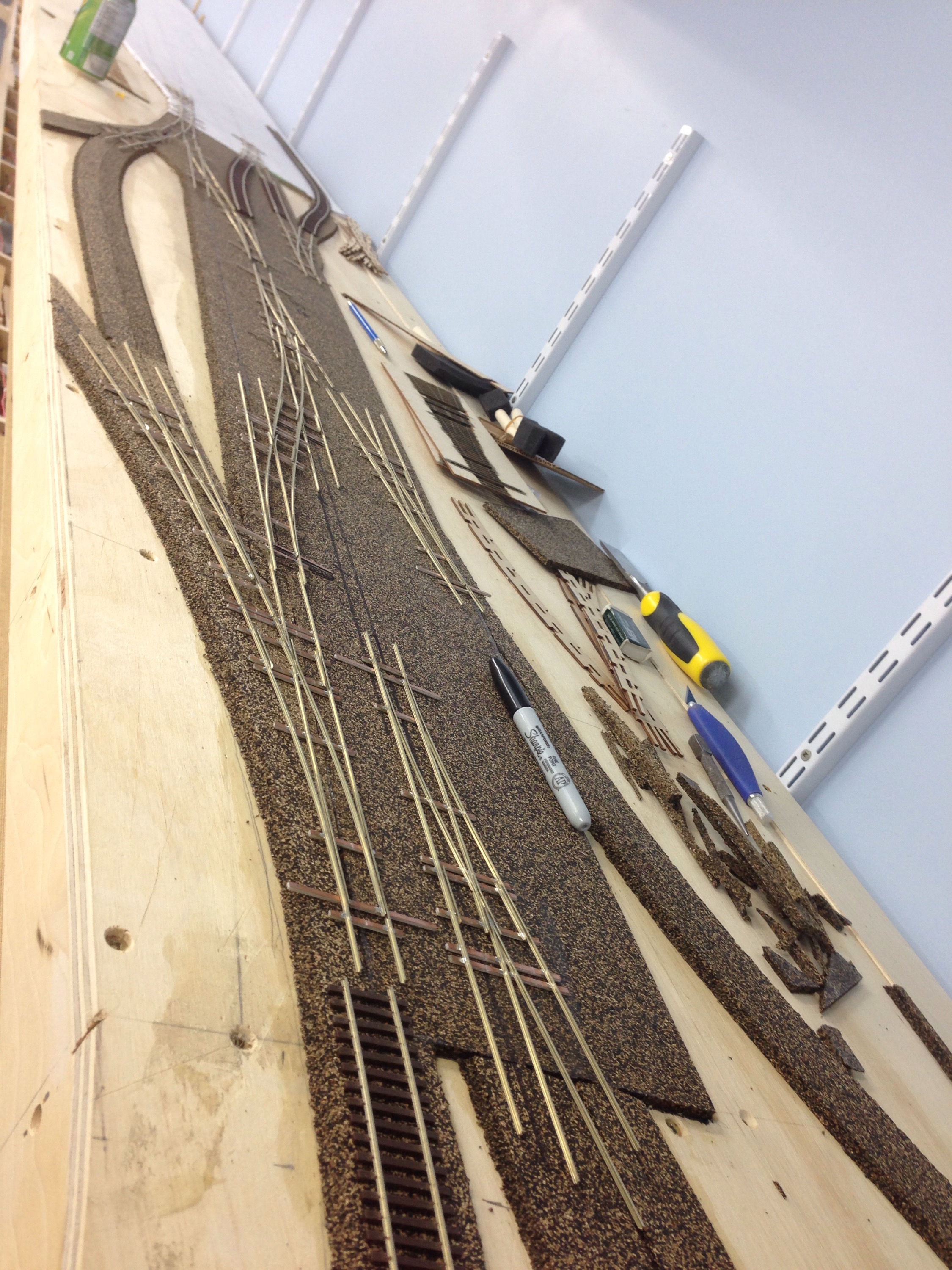

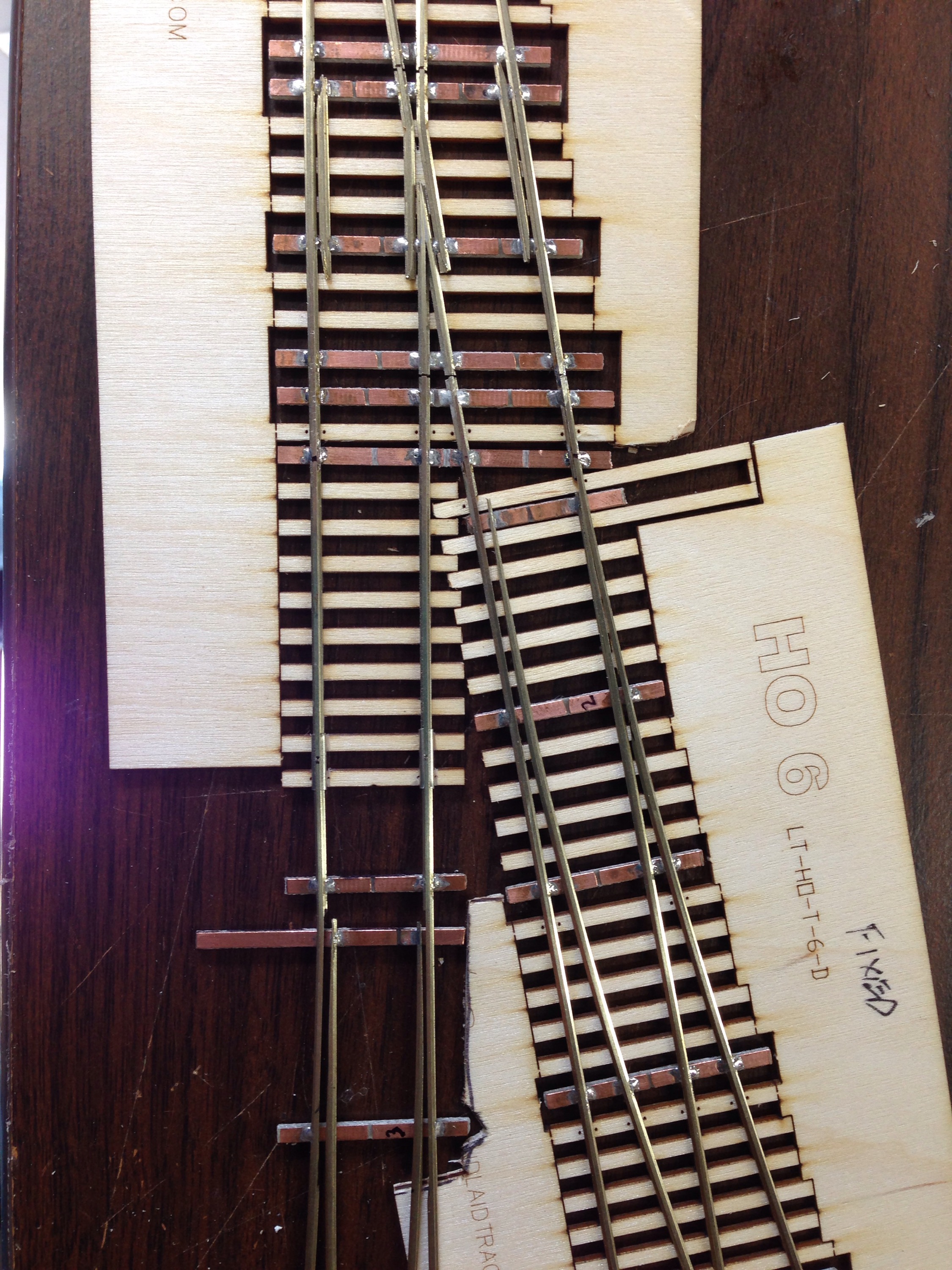

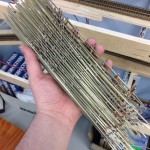

- COVID-19 struck about a year ago, and while I was working for most of the time, there was about a month and a half where I was working 4 days a week instead of five. With that extra day off each week, I figured I’d bite the bullet and actually redo the entire staging yard to support Marine Interchange. More on that specific bit shortly, but with the scalehouse coming to the layout, and a bunch of extra time, I figured it would be well worthwhile to add some more operations to the layout and am adding a ferry slip. To do that necessitated a full on lifting of the majority of the trackage in the yard and laying it again in a different configuration. I’m also making the yard slightly more reminiscent of the prototype, though only in that the caboose track is going to be adjacent to the scalehouse, the engine service and RIP tracks are going to be present, and I’ve got a pair of team tracks to service. I also sold off four 40/30″ radius curved turnouts as they wouldn’t fit along with a funky crossover. The remaining turnouts were repurposed elsewhere in the yard and more than a few new turnouts were made, including the acquisition of yet another turnout assembly fixture from Fast Tracks capable of building curved #8 25/32″ radius turnouts. I built a few of them, including one during a Facebook Live event. At some point when the layout is clean, I’ll possibly take some pictures and post an updated track plan.

- As indicated above, I decided that I really, REALLY, wanted marine interchange. This goes back to the early track plans where I had planned on having a boat to switch, but had to give up after discovering a few gotchas during the building of the layout space. After doing more than a few switchings of the Doris Yorke and the Trailer Princess at David Bedard’s place back when he had the E&N, I wanted it still for myself. On the prototype back in the day, the Seaspan Doris and the Carrier Princess were the primary boats doing the work of transporting railcars between Vancouver and Nanaimo. I do admit, I was tempted to get the Doris Yorke from David when he was selling it, but decided that I really wanted the Carrier Princess instead. So I’m going to be building a scale model of the boat and putting it on wheels so I can actually “sail” it into and out of a ferry slip that is going to be roughly underneath where the middle deck Victoria Sub goes into the helix. This will allow me to give more work to the Nanaimo switch job – they’ll be responsible for unloading and loading the boat, classifying the cars going to the Port Freight, the Courtenay Turn and the Nanaimo switch job. I have my doubts that I’ll be pulling and spotting traffic that headed to Duncan and Victora though. The yard isn’t big enough for all of it.

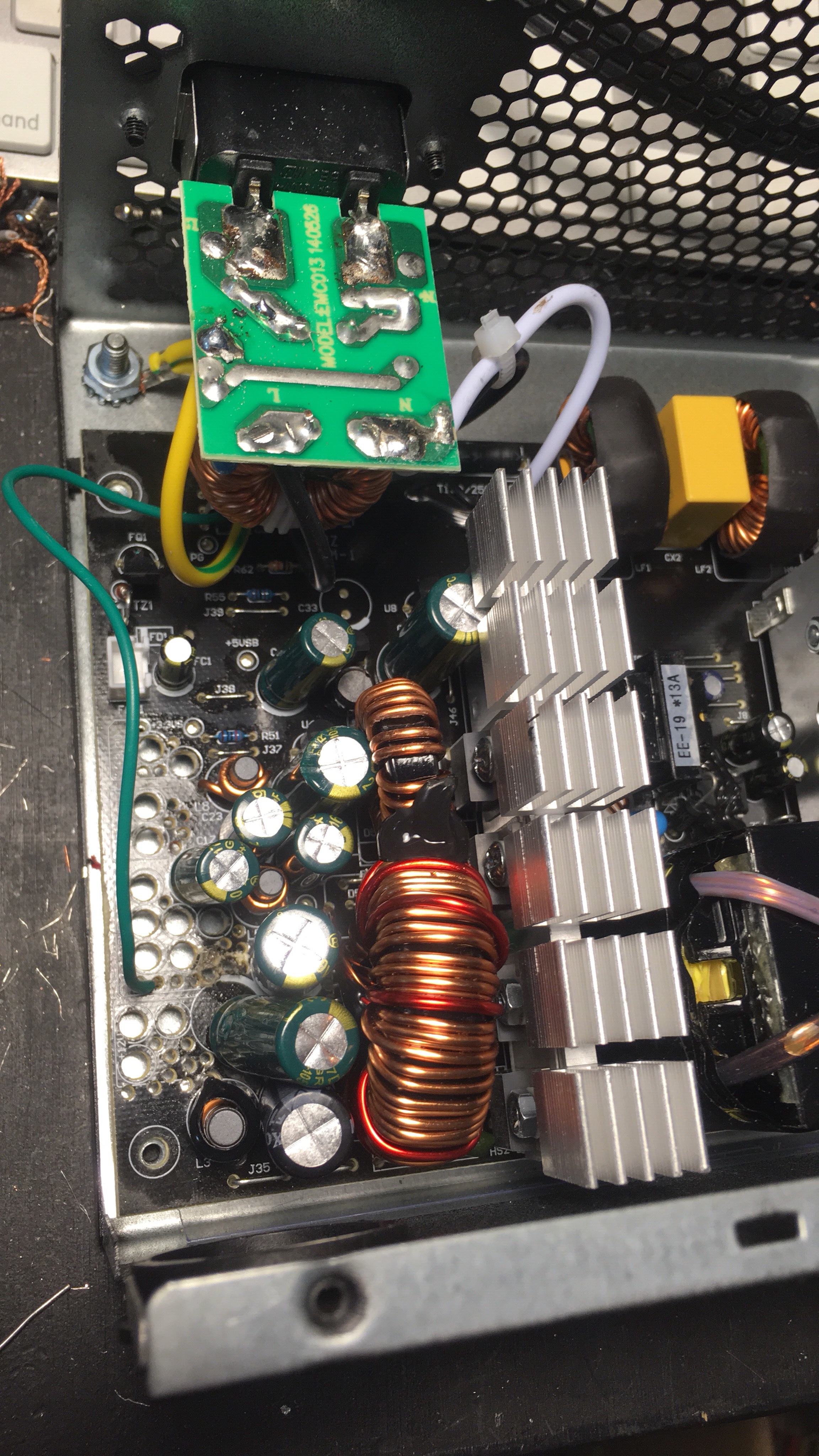

This is going to require my spray booth to find another home – quite possibly out in the garage or perhaps even in my office upstairs. - In the rebuild of the yard, I decided early on that I wanted the ability to control the turnouts from touch panels. This eliminates the need for operators to know the switch numbers and for me to build physical panels. With all the turnouts being controlled by servos driven by Quad-LN’s from Tam Valley Depot, it should have been an easy thing to do up. Except…Well, let’s put it this way. I should’ve been able to have this entire yard done and controlled months ago if it weren’t for a number of things being problematic, like my Locobuffer-USB missing commands, the Zephyr command station not putting enough voltage into RailSync, the old iPad I acquired for the purpose not being new enough to handle the panels JMRI was handing out, and changing out the layout computer to one that is a little faster and equipped with more memory. It’s been very frustrating at times, but thankfully, everything is now properly working. I’m still working on the panels, but that should be completed reasonably soon.

- I’ve found a number of the servos in Port Alberni to be hanging from the layout every now and then, because the double sided tape I was using to hold them to the layout was losing it’s bond under the heat from the servo. Cam has been on my case for a while about getting a mount made for them so I can screw them to the layout. With the help of Chris Caswell in Nanaimo and his laser cutter (he runs BC Robotics), I’ve managed to design, prototype and make a bunch of three piece wooden mounts that are absolutely brilliant at having a servo do the work it needs without requiring a huge amount of space to do so, but yet providing a neat ability to adjust the position of the servo if needed after screwing it into the benchwork. My friend Andrew Underwood has these installed on his small switching layout and really likes them. I like them too…so much so that:

- I’m going to pull all the bullfrogs from the layout. I’ve already replaced the lower deck of the layout with Tortoises controlled by the Signalogic Systems Tortoise Controllers and Switch Control Panels, and will be replacing the remaining bullfrogs with servos due to the deck height limitations. This way, I can have all the turnouts (save for the ones in the Wellcox yard) controlled by a common interface that provides for route indication from the fascia.

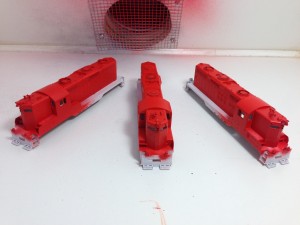

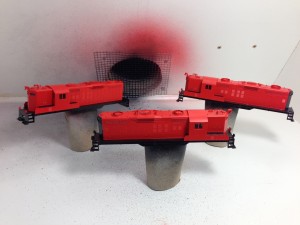

- I finished up the process of acquiring, stripping, painting and decalling of a bunch of 50′ Proto2000 Flatcars into CP Rail Action Red. I now have proper spacer cars for the loads of poles coming out of the Courtenay Area. Also acquired a lot of Action Green boxcars for paper service. I still have two cars that I bought undecorated to suitably modify, paint and decal. Just need some pulling eyes to complete the modifications…Which leads me to my next point:

- I’m getting a 3D printer. David pointed out the fact the Elegoo Mars printers (he has a pair of them) were available on sale at Amazon for just $220, delivered, and I couldn’t really pass it up. Add a bottle of resin, a UV Curing lamp, cabinet for said lamp, and you’re virtually all set for less than $300. Plenty of detail parts will be coming from that over the next while, and perhaps even a caboose? It’ll be a rabbit hole to be absolutely certain!

Maybe, just maybe I’ll find more time to do updates to the blog, but this will do for the time being. See you in a couple years!

Recent Comments