July 13-14, 2013

A brief update…even though there was plenty of work done.

Over the course of the time spent downstairs on Saturday and Sunday, I got feeders dropped and secured to the rail for the entire ICG Nanaimo – Nanaimo depot sub-district. Not wired into the bus, but that will hopefully be completed this week. I also gapped the rails for that power district as well.

Cam was over for Saturday and some of Sunday and worked on getting track laid in the staging yard. Made really good progress too, having completed all but a few tail tracks on the southern end of the yard and half of the runaround track. Sunday saw the last bit of staging yard benchwork completed – that is, the reverse leg of the wye into the programming track, and a lot of that track is fitted, though still needs to be spiked down. We also found that cheap birch plywood has another nasty trait – loves bending the track pins! Coupled with the splintering capabilities, I can’t say I will recommend it for benchwork again.

I’ve also been working to get a servo programmed to become the block for errant rolling stock headed to the abyss. Mostly successful, but not entirely positive I can get the Singlet to function as I need it to – that is, having a microswitch operate as a toggle… More to come on that…

Cheers!

July 7, 2013

So it’s been a little while since my last post but I’m still working hard to get things ready for the end of the month.

Yesterday began with some cleaning of the basement – it’s a real disaster down there – and getting things lined up.

Since making the decision to go with servos instead of much larger and more expensive tortoises, I’ve acquired the Quad-LN’s from Tam Valley Depot, the servos, wiring and microswitches from eBay (servos for about $2.50 each, at my door, microswitches for 17 cents each, wires free due to a sharing deal with Dave Bedard) and after all is said and done, I have a DCC controlled turnout for less than the cost of a tortoise bought in a 12 pack… And that doesn’t include the other bits needed like a DS64 or the wiring involved.

Installation of these servos started yesterday and the Quad-LN’s were installed as well. Sadly, I neglected to order an aligner for the Quad-LN’s and the instructions indicate one is necessary to properly set them up. 🙁 I tried a few programming things but in the end, nothing did as it was supposed to, likely because the power supply I was using couldn’t pump enough juice. The Quad LN says it needs about 750 milliamps of power and the supply I used only provided about 300… So I’ve ordered an aligner and a 5amp power supply from Tam Valley. Hope to see them soon.

Meanwhile, Cam was busily getting turnouts laid in the staging yard. We’ve got a lot of track still to lay and I’ve got even more basement to clean up, track to wire and more to do…will get some more done tomorrow.

Cheers!

June 8-9, 2013

Despite appearances to the former, I have been working on the railway over the past while. Just haven’t had much time to actually write about it.

Where to begin:

The track plan for the staging yard has been (almost) finalized. A couple weekends ago, Cam and I were working on the plan for the benchwork and we got to discussing the end of the staging yard. Specifically, how to terminate it. Owing to a lack of feedback from a much earlier post of mine, we decided on a curved turnout ladder and bending the track towards the main helix. The reasons to take this route as opposed to a sector plate or a transfer table, despite their much lower costs and space requirements, are a longer track for the Port Alberni Freight, a longer tail track, and as we discovered, longer storage tracks and a possibility for a couple loco storage tracks.

So with that plan in place, we’ve been building benchwork to make that happen and I’m pleased to say we’re done the benchwork for the staging yard.

Cam said it might be a good idea to just continue making a mess and finish the benchwork for the entire layout while we have the opportunity, and get it done and over with. Can’t disagree with that, so we’re now working on the benchwork for Port Alberni… Another weekend and we should be done!

Also of importance in this work is how I’m going to be powering turnouts in the staging yard. David Bedard has been a fan of using RC Servos for turnout control and showed me a lot of benefits for using them. Prime among them is the cost. These things are very inexpensive compared to the cost of just the tortoises themselves, let alone the time involved in hooking them up… These things are small, plug and play (literally, no soldering required!), and robust. After all, these servos go into model airplanes which means if they fail, it usually ends up with said airplane corkscrewing into the ground with really, REALLY disappointing results!

As a result of the decision to switch to servos, I’ve got a pair of DS64’s for sale. Make me an offer…

And lastly for this update. Jason Shron (of Rapido Trains fame) will be visiting my layout again at the end of July. He’s expressed interest in participating in an ops session or two while he’s here. After hearing of the progress on my layout (which has been really substantial since he last saw it) he managed to convince me to have one.

I agreed to the idea of a partial ops session (not involving any switching in Port Alberni) and then realized how much work is involved… I suppose nothing lights a fire under one’s ass like a deadline like that! Better get to work!

May 26, 2013

Simple update from yesterday’s small amount of work:

Installed six bullfrogs, and trimmed the throwbars to length. Also had to run to get #6 screws as that’s the only size which fits.

Tonight is running bus wire.

May 18, 19 & 21

This past long weekend was a very fruitful session of track building!

Following a lot of benchwork being completed over the previous weeks, we now have track laid pretty much all the way from just south of Bryn through to the Nanaimo depot. Yes, the saying, “we’ll cross that bridge when we get to it” applies here as last Tuesday, we now have track onto the drawbridge separating the staging trackage from the rest of the layout.

In addition to the great amount of trackwork done (which includes trackage into five industries), I’ve got bullfrogs built for all of the switches, though they still need to be installed.

And one last thing. Dan spent a bit of free time and punched a hole through the wall where the staging yard will come through the wall from the utility room.

April 29, 2013

Finished up all the feeder wires and the bullfrogs in Courtenay this evening. Accordingly, I am now able to run freights all the way north… But until I get the layout vacuumed, nothing’s getting there!

Tricky benchwork

Spent a fair bit of time with Cam and Dan this past weekend. Saturday was primarily spent measuring, checking with levels, and a whole lot of cardboard being drawn on.

Now that the bridge is in, the work of getting to the staging yard is now underway. The big challenge is that there’s a wye into my future programming track and the main route to the staging yard itself happens to be in rather tight quarters. Specifically underneath the stairs to the basement and clearances in spots are tight as hell. Thus, the planning needs to be quite good because we don’t have ability to lay track on said benchwork after it’s installed. This also includes turnouts and their switch machines.

So the need to get it all bang on the first time is quite important.

Sunday had Dan and Cam over to start making lots of sawdust (and I just vacuumed it all!) in constructing the bits. Well, most of them. We’re still working on the one leg of the wye, but we ran out of time on that. More to come in weeks ahead.

Getting to old tasks

This past week has bee an interesting one. Of course SUPERTRAIN wrapped up last Sunday after a spectacular weekend and record attendance, and had a few people over to see the layout. Needless to say, Dan Garcia and Matt Soknacki of Rapido Trains were quite keen to see the layout as were a few others, including Steve Stark. Steve was introduced to me by Tim Horton (of BCR Dawson Creek fame, not the coffee shop) as a fellow E&N modeler. Steve is also an absolute fount of knowledge about the industries on Vancouver Island, and as a result of him, I’m needing to pull up a very short length of track at the end of the Superior Propane spur in Parksville and replace it with… Get this… Code 83 rail on Concrete Ties. Yup, there’s a 100′ long chunk of 132lb rail on concrete ties in the hydrogen peroxide facility. Yup, that spur was a dual-purpose bit of track according to Steve… Served as both hydrogen peroxide and propane!

In the past few evenings, I’ve also been taking care of a more necessary task, running bus wire and properly powering up the lower helix. After getting the bus soldered to the clips and then secured to the ready rod, gapped the rails at the lower end to ensure two boosters weren’t feeding a common set of rails, and made the connection of the bus to the appropriate PSX unit.

Fired up the system, did the quarter test and all good. And then I sent the Courtenay turn north from Parksville. Shortly after the train departed Parksville, I got sparks and beepage from the booster. Turns out that I have a DB150 which has the rail sync … Well, out of sync. A quick change of the output wires and problem solved.

Started the turn back down the hill and put the dayliner into service at Courtenay and had the two meet at Mud Bay. I suppose I should’ve taken a photo to commemorate the moment, but didn’t. Was having too much fun!

April 6, 2013 – The Bridge is in!

Really wanted to get some really meaningful progress done on the layout this weekend and made it happen. This past Wednesday, went down to Murray’s place and borrowed his router (and bits), and lined up assistance from Cam and Dan for Saturday.

We tore apart (again) the area around the Vancouver Island Gas spur, to allow for better scenery work, then built the trackboard down to the depot.

And then we built a bridge!

A fair bit of thought (and purchases) went into engineering and building this movable bit of benchwork, primarily because I vowed after hitting my head on a duckunder at CMT, that I would never have to bend over to get into the basement. Though there is a major crawl to get into the dispatcher’s desk, the rest of the operating session crew should never have to bend over to access any of the trackage. Anyhow, after much deliberation, we decided on a lift-up bridge rather than a swing bridge as originally intended for the access to points south of the Nanaimo depot. Lots of measuring, cutting, routing and then plenty of glue (of two types – the regular yellow carpenter’s glue and a polyurethane glue) were used to bond the wood and metal together. Here’s the bridge in the closed position:

And in the open position:

Yes, I know I need to install a doorstop or some such device to prevent the drywall from getting dinged too badly, but the hinges do assist in ensuring the bridge won’t fall down unattended, and provides some assistance in lifting it. It’s still very much a manual process to open or close, but it’s nowhere near as much work as it would be if there was no spring in the hinges.

I’m still needing something in the way of an alignment pin to keep a lateral alignment certainty but the brass latches on the underside make sure the vertical transition stays as it should.

We also need to get cork and track laid, but it’ll likely be after SUPERTRAIN before that happens owing to the time needed to build two curved #8 turnouts, two #7 straights and two #6’s for the trackage needed up to the bridge.

I should also really get the wiring finished for the lower helix and the rest of Courtenay yard too… Lots to do for sure before the next major bit of benchwork: the Staging Yard!

Cheers!

The past few weekends, and a Good (progress) Friday!

So I’ve been busy, and to be honest, not terribly inspired to write about the progress made on the layout.

But progress has definitely been made! A few weeks ago, I did a fair bit more wiring work to the Courtenay site, and we can (in theory) run trains all the way to the depot in Courtenay…. Which is good for the dayliner, but not for the Courtenay turn which needs access to all trackage in the town to do what it needs to do. That will come in time.

But more importantly…

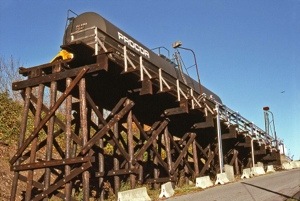

We have benchwork into Nanaimo! Cam, Dan and I worked over the past couple weekends to get benchwork built and this past (Good) Friday, Cam and I got track boards installed south to Vancouver Island Gas. This spur is rather interesting because of … Well, here’s a picture that explains it all:

Cam and I have also worked out a solution for the bridge across the aisle to the staging yard. Instead of being a lift-out or a swing bridge, we decided on something more resembling a bascule bridge. It’ll swing up to vertical over the fridge, and the best part, we’re using self-closing hinges. The weight of the bridge will keep the pressure light when the bridge is down, but assist in raising it and will also ensure it stays open when it’s up. Of course, given the fact we need to incorporate a grade along the line to the VI Gas spur means we’ll need to incorporate some mechanism to keep rolling stock from going to the great abyss if it’s not connected to a locomotive!

That we’ll figure out over the next while…

Till then,

Cheers!

No further track laying north!

The northern end of steel has been reached! Granted, wiring still needs to be installed in addition to some yard trackage in Courtenay, and some bullfrogs also need to be installed, but the mainline is in!

January 21, 2013

Spent a few hours last night separating bundles of salvaged 12 and 14 gauge wire (thanks Dan!) into appropriate colours, and then got to work installing the remaining pair of PSX-3’s. Lots of screws and nylon spacers getting the boards secure.

Wiring in the things reminded me why I prefer solid wire for these things. And even though it says the terminals are rated to fit a 12ga wire, it only JUST fits, and even then requires a lot of pushing and angling things just so, and that’s not counting the stranded wire frustration. I ended up using 14ga solid wire for the pass-thru connections.

January 20, 2013

Wow, been a little while. Happy new year! I’ve been a little busy with getting things in place for SUPERTRAIN, and late this past week determined that I need to have the layout to a point where I can have a mini-ops session by the time mid-April comes around. I say mini because I’m wanting to show off the layout when a few friends arrive in town for the big shoe, but I know for a fact I’m not going to have Port Alberni in place in that sort of timeframe. Nanaimo, and staging, on the other hand, should be doable.

Spent an hour downstairs on Saturday and most of Sunday getting lots of little things done. Specifically, eight bullfrog switch machines and another turnout for Courtenay. Cam arrived in the early afternoon and set to work on the trackwork into Courtenay itself.

At the end of the afternoon, we’ve got track up to the south siding switch of Courtenay. So for the lower deck, needing to get everything around the walls wired, lay track in the Courtenay yard, lay track for the team track and ICG, and install the bullfrogs. Not much work really.

Which then leads to getting benchwork installed for the second deck, getting track installed and then comes the bigger question of exactly how I’m going to build/operate the connection across the aisleway to staging. We’ll (sunglasses) cross that bridge when we get to it.

December 29, 2013

Spent this morning washing a bunch of turnouts and then assembling them with the quicksticks. Found one of the skeletons I thought was originally code 70 was actually a code 83 turnout which is for the staging yard. Oops.

Cam came over and we got to work on finishing the cork to Courtenay. After that was done, the track laying came. Cam got started with continuing the trackage north from Union Bay, and I started in on another turnout skeleton, occasionally providing my eyes to the progress and ensuring the track was kink free.

Dan arrived after he finished up work for the day around 6. He joined Cam with the track laying stuff, and I got to work on making the little clips to wire in the bus to the lower helix. Once there was a fair amount more track installed, I worked on hooking up feeder wires to the track. By the time 9:30pm rolled around, we were getting to the “done” point, and called it a day.

To sum up, we have cork down all the way to the northern end of track in Courtenay, only two turnouts need to be finished and track laid to just past BC Pole. A very good day of progress!

December (mumble), 2013

As much as I dislike Omnibus type things, I’m afraid I need to use it here…

I’ve been down to the basement quite a bit over the last few weeks and haven’t been doing any updates to the blog so my apologies to James and my other lurker readers for not doing these more frequently.

After getting the track boards cut, they spent a bit of time being left alone but they did get secured not long ago. Shortly afterwards, Cam and I cut a board and attached to the wall right at the bottom of the stairs. This will form the tail track and the northernmost trackage in Courtenay. This will come in handy for the crews working the Courtenay turn as they’ll likely need to do some shuffling of cars to switch on their way back to Nanaimo, as the vast majority of the turnouts are south facing.

I’ve also been busy building turnouts, mostly #6’s, but also a #8 curved turnout as well. Much as Cam would like Courtenay and the trackage into it to be arrow straight like it is in the prototype, my basement just won’t allow it, and I’d rather not give up a couple important industries (BC Pole and Dominion Tar) to accommodate that wish, so the turnout to the Courtenay team track will be situated on curved trackage. As far as we can tell, all industries in Courtenay in 1988 are present and able to be switched. I’m looking forward to operating it!

As we hosted a Christmas Brunch for a few important family members, I wanted to get the basement into some semblance of order and also do massive cleaning to make it presentable, I spent about three evenings getting a lot of cleaning/organizing/purging/etc. done. The results are fantastic. Family loved it, trains ran (though admittedly some dirty track in the helix caused some angst, more on that later) and all was good. I even spent the better part of a couple hours tonight doing the same to my workbench.

Couple days ago, spent a few hours in the morning to finish painting the stairs into the basement. Just plain white primer for now.

As I eluded to earlier, some dirty track has been bothering me. More due to all the dust in the basement, something rather unavoidable with all the construction happening, I decided to take advantage of the Boxing Day sale at PM Hobbycraft and looked at an Atlas track cleaning car. To the best of my knowledge, it’s the only vacuum equipped car, so picked it up and then proceeded to install a DCC decoder into it. I ended up removing all the wiring inside, hardwired the decoder in and after a bit of programming, am now able to control the speed of the fan. Ran it successfully through both helicies in front of a couple GP38’s. the results were promising. After a couple runs, the hopper was showing a few bits and the screen was covered in fine dust. The unit could definitely use a capacitor to assist the vacuum motor, and a couple other tweaks, but I’m satisfied with it. I’d post some pictures, but they’re too dirty. 🙂

Yesterday, spent a couple hours and laid some cork down through BC Pole and Dominion Tar as well as the mainline approaching both. Should have the rest of the cork laid tomorrow and probably some track soon as well.Had a real SOB of a time trying to get the lid unscrewed off the full 1.5L jar of contact cement though. I now own a couple strap wrenches…

Also received my order of track yesterday too. 10 bundles of code 70 flex, totaling 180′ of track, so should be good for a while. The three existing bundles weren’t going to make it to Courtenay. While we were out shopping, also picked up some 14ga stranded wire from MRO in red and black for bus wiring needs. My PSX-3’s finally arrived a week or two ago and I can get them installed.

Can’t think of anything else to mention. Thanks for reading this far!

December 2-5, 2012

So I’m finding the workflow with the registrar duties for SUPERTRAIN to be a little less hectic, and Cam found himself with a little extra time, so we got some additional work done downstairs. We’re now in the final stretches of getting all of the benchwork into Courtenay done. All the track boards, minus tail track well north of the Courtenay depot) are cut (including one spur I cut solo on Monday) and ready for installation!

We also checked the lengths and ensured we could fit at least a three-car pole set into both Dominion Tar and BC pole. And in fact, we could actually fit a five car set into the Dominion spur!

And over the past few evenings, I’ve been building turnouts again. I’m needing them and figured track installation is imminent… Two #6 turnouts are now built for the pole yards. Next up is the ICG spur in Courtenay, and then a curved 30/40 turnout for the Courtenay team track. Of course, the track into Courtenay is pretty much arrow straight, this making a curved turnout unwanted, but the layout dictated it to keep the number of separate curves down.

I’m also debating another open house this year after Christmas to show off the progress, but haven’t come to a decision as of yet. If you’re interested, drop me a line – either via email or a comment to the post.

November 13, 2012

Made a lot of sawdust tonight on just five jigsaw cuts. Admittedly most of those cuts were in excess of four feet long each. And this is what I made:

No, it’s not a wooden saguaro cactus silhouette (like the ones used in the night time scenes of Silver Streak) but rather the trackboard for Dominion Tar & Chemical. The spur on the right is where poles were loaded into three and five car sets for shipment all over the continent to be used for power poles.

It’s not much, but it’s still progress.

November 10, 2012

With my wife out of town on a two week holiday to Hawaii for scrapbooking, I finally took some time to get to work on the layout. Of course, also good that Dan and Cam were willing to help.

Some time ago, I acquired a couple display cabinets from another model railroader who was moving and downsizing. After sitting in the basement since spring, I finally have them installed on one of the unclaimed walls.

And then we got some work done on the trackboard into Dominion Tar & Chemical, drawing out where the main and the spur are going to go. Room for a 3 car spot plus a little more. BC Pole was also factored in and then since I could do some of that stuff on my own at a later time, figured on getting more of the benchwork done which does require a few more hands. And with that, we installed benchwork around the “nose” of the basement (south end) for the lower deck, and we now have the basic shape for Courtenay. We also found better spots for ICG in Courtenay, along with the team track across Cumberland Street from the station.

We ran out of usable 2″ wide plywood, so we’re not quite done with Courtenay’s benchwork, plus I’m needing to install a narrow shelf into the stairway for the escape track out the extreme north end of Courtenay’s diminutive yard. Next weekend, I should be able to acquire more plywood in the correct dimensions and carry on with the task!

Of note, it would appear Layout Tours for the CMRS have been moved up into March… If I’m going to have the Victoria Sub portion of the layout operational by then, I should get a move on!

August 12, 2012

Been a while since I’ve identified a post under “basement development”, but the work Cam and I did this weekend was certainly that work.

Saturday, we made a quick trip to Home Depot, picked up a sheet of 3/4″ MDF and four strips of pre-primed moulding. The sheet of MDF was ripped there to 10 1/2″ and 10 3/4″ wide, per the quick measurements I made earlier in the week.

Sunday morning, I went downstairs and got to work putting a coat of primer on the sides and one of the faces, as well as finishing up the trimming of the drywall to the proper size.

Later that afternoon, Cam came over to assist with getting the shebang installed. After finishing the priming od the bloards, we needed to make a trip to Rona for some ‘tuck tape’ which I needed (but didn’t realize when we picked up the other stuff), we got to work on cutting and installing the casing.

And here’s where I found that the window wasn’t installed very squarely in the opening. A few custom cuts later, we had everything secured, and got the first piece of moulding nailed in. And then pulled it out owing to the fact the brads I was using were too short. Redone with 2″ long brads, all was made secure.

Still to be done is filling of the screw holes, nail holes, siliconing the seams and corners and for this window, applying some small moulding to hide the distance between the casing and the window.

Cheers!

August 7-8, 2012

Since the weather is rather warm in Calgary, decided to head downstairs to the basement and cool off, admire the work done thus far, dream a little bit, and just generally cool down.

While I was sitting there at the location soon to be occupied by the team track of Courtenay and Vancouver Island Gas, I looked at the standards holding up those far-from-level brackets and realized a rather important fact:

The standards are not necessarily plumb.

There are some curves in the standards, either from a rather zealous drive from the drill securing the screws, the taping and mudding on the wall not leaving a rather flat wall, or likely, a combination of both. So with the curve in the standard, the shelving brackets, especially the long 19″ ones, are pointing up. Thankfully I discovered this before much work was done and the fix for this is reasonably easy to implement. We’ll pull the brackets, pull the screws and shim the standards so they are straight and secure. That should fix the levelness of the brackets.

I also realized that if I’m going to get the windows finished, I should do so fairly soon, lest the work become a hell of a lot more difficult owing to the fact that the layout in front of the window at Port Alberni will be very deep… Cam agreed on this fact and told me to get the drywall prepped (ie: flush to the window frame) and on Saturday afternoon, we’ll acquire the casing and boards and get the windows finished. So, over that evenings and Wednesday, I’ve been getting reacquainted with the drywall saw, utility knife, rasp and most importantly, vacuum cleaner and getting that task taken care of on both windows. I’ll probably need to replace the vapour barrier on both of them owing to the fact that it doesn’t take well to long-term exposure to UV and my punctures with the saw.

Cheers!

August 6, 2012

What a day of progress!

Cam came over in the morning and we got to work on getting benchwork built for the lower deck. But before we did that, I wanted to get that chopsaw stand that Murray brought over on the 21st into action. Turns out that shelf I was going to use (the top off the table my brother made eons ago) was the perfect size for the base of the chopsaw, and shortly after, the chopsaw was secured using bits of ready-rod, spare nuts and washers from the now-complete helix construction, and we can finally use it as intended. I even have the ability to do much of the work solo now that I don’t have to have someone hold up a long piece of wood.

Once done, we got to work on the lower deck benchwork, as well as the middle deck too, in some respects given that the deck depths were going to be the same. Stop blocks were installed on the saw and we chopped up a lot of the 2″ wide strips into dozens of fingers.

Holes were drilled through all of them for bus and accessory wires and voila. Half the job done…well, not quite. Lots of other things needed doing, like drilling holes through the shelf brackets for securing the wood to the metal brackets, cutting the pieces to good lengths, splicing them together, and then getting the works secured to the shelf brackets and to the wall at the south end.

That chewed up a very good portion of the day and then we started mocking up how the rest of the decks would play out, and it turns out, quite well…Well, almost. I was hoping we could simply screw from underneath the brackets into the 3/4″ plywood for the upper deck, but initial appearances showed that many of the brackets were pretty far from level, and no idea why. We’ll investigate later as to potential solutions.

Cheers!

August 5, 2012

I knew Cam would be busy with family today, but had a project that I knew wouldn’t be too hard to complete solo, and that was the installation of electrical power for the chop saw into the peninsula wall and also in the inside of the dispatchers booth, primarily for a computer or lights, or even a charger for radios.

Using some 14/3 household wiring, plus the bits I picked up yesterday, went about drilling holes through the 2×4’s and then stringing wire. A couple boxes secured to the wall, outlets secured to wires, and faceplates attached, I set to the last task and that was terminating my “semi-permanent extension cord” with a male plug which then plugs into the actual electrical circuit near the end of the wall. With everything plugged in, and I went to test it. Couldn’t find my circuit tester, but figured my voltmeter would verify power just as well, and found it read 148 volts.

Oh crap. That’s way high.

Tested a few other spots and found them high too.

Called Cam later that evening and he reassured me that the household wiring was fine, that things would’ve went poof a long time ago if that voltage reading was correct and that he would be happy to test the house with his multimeter. Sure enough…my multimeter is now usable primarily for continuity and that’s about it. Guess who’s buying a new one? I’m not that terribly concerned, it’s given me many many years of life, though now I’m beginning to doubt just how accurate the measurements I’ve made have been as of late…Perhaps my accessory bus isn’t actually around 17V, but more around a normal 12? We’ll see when I pick up a new one.

Cheers!

August 4, 2012

Murray and Cam came over early in the morning to put some time in on the layout and we managed to accomplish the installation of a fair number of the shelf standards (thanks to Murray for bringing his 6′ long level), and now we have standards on two complete walls with a plan on how to start into the nose of the basement.

We also discussed aspects of copying this system over to Murray’s new layout, and discovered I needed a few things. One was an additional 4′ long standard to help close the a rather sizable gap (give or take 30-35″), Another was a full sheet of 3/4″ plywood which would become the prime bit of benchwork for portions of Port Alberni, and lastly, I wanted to put 110V AC power into the peninsula wall, and needed some bits for that to happen. Murray has a pickup truck, Cam and I do not, so we figured it would be worthwhile to take advantage of the transportation opportunity.

After returning to the house, we met up with a friend of mine, Matt Buchanan, came over while he was in Calgary to take a look at progress on the layout. He’s planning on a little switching layout with a portion of Vancouver’s downtown. While the four of us were there, we got that 4×8′ sheet cut into two pieces, one representing the eastern end of Port Alberni and the other the area around the ICG spur and the Port Alberni enginehouse. After that was done and Matt had left, we decided a hobbyshop crawl was in order. Michaelea and I left for Lee Valley to pick up the stuff there that we didn’t pick up in the morning, Murray and Cam left for an errand Murray had to take care of and we met at Trains and Such and then went around the south end of the city to a few shops and ended up at Kelsey’s for dinner.

The rest of the evening was spent playing down at Murray’s layout. More would come on Monday!

Cheers!

Recent Comments